A.Power supply circuits

Stable DC power supplies are divided into intermittent control types (switching regulator) and continuous control types (Dropper).

Recent trends have shown an overwhelming growth in switching regulators, and so we talk mainly about switching regulators below.

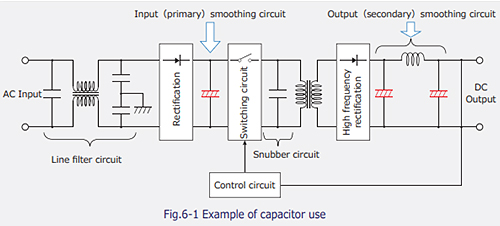

The capacitors used in switching regulators are selected depending on the circuit. A forward switching regulator is shown as an example in Flg.6-1. Another type is a fly back regulator.

(1) Aluminum electrolytic capacitors for input (primary) smoothing circuits The Aluminum electrolytic capacitors for input smoothing circuits used on commercial voltages (100 V.AC, 200 V.AC) and commercial frequencies (60 Hz, 50 Hz) must have a high withstand voltage and a ripple current resistance complying with twice the commercial frequency (normally full-wave current).

These capacitors have large volumes (ground contact areas) compared to other components they are assembled with ,and so the demand for more compact capacitors, as well as power supplies, is strong. Another problem is the need for longer aluminum electrolytic capacitor lives, but products guaranteed for 5000 hours at 105℃ have recently been developed, thus realizing freedom from maintenance for 10 years.

(2) Aluminum electrolytic capacitors for output smoothing circuits The rated voltage of aluminum electrolytic capacitors used for smoothing at switching frequencies (20 k to 500 kHz) is determined by the output voltage, and they must have low impedance (low ESR) at switching frequencies. Therefore aluminum electrolytic capacitors for output smoothing are designed to have low impedance at 20 k to 500 kHz, and the recent development of a low resistance electrolyte using new materials has resulted in products with 1/3 to 1/4 the impedance of conventional products with the same volume. These low impedance products also have an extremely stable life

B. ECU for automotive

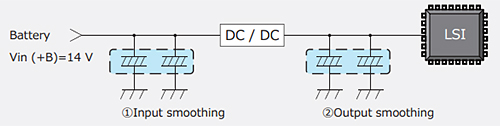

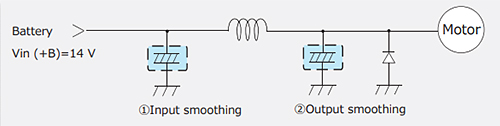

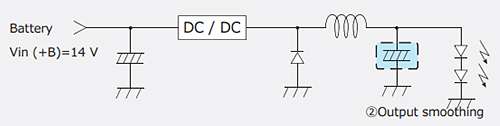

The electronization of in-vehicle control is accelerating these days. ECU (electrical control unit) which carries out in-vehicle control is asked for high reliance, a miniaturization, and high quality, and many aluminum electrolytic capacitors are used for it. A typical application example is shown below.

(1) Power train ECU (Engine、 HV-Inverter etc.)

(2) Motor control ECU(Power steering, a blower / radiator fan motor, an electric pump etc.)

(3) LED lump

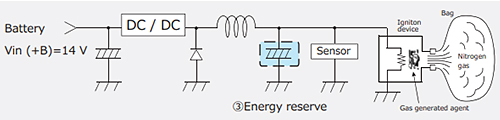

(4) Airbag

In automotive application, there are mainly an object for smoothing of input and output of the power supply of ECU and an object for energy reserve.

The rated voltage of 25 to 50 V.DC is mainly used.Not only current aluminum capacitor, aluminum capacitor with conductive polymer and

electrolyte is increasing due to improve quality, performance, with standing-voltage.It contributes to the small size of ECU, and a weight saving these days.

No comments:

Post a Comment